In the fast-paced world of the automotive industry, precision and efficiency are paramount. To stay competitive, manufacturers must embrace cutting-edge technologies that optimize their production processes and deliver superior results. One such technology is Computer Numerical Control machining, a revolutionary method that has transformed the automotive manufacturing landscape. With CNC machine, automotive companies can enhance their capabilities, streamline production, and achieve unparalleled levels of accuracy. In this article, we will explore five crucial ways the automotive industry can leverage CNC machining to their advantage.

1. Prototyping and Design

In the automotive industry, product development heavily relies on rapid prototyping and design validation. Traditionally, creating prototypes was a time-consuming process, involving complex setups and manual labor. However, with CNC machining, this task has become significantly more efficient and accurate. By feeding detailed digital designs into the CNC system, manufacturers can produce intricate prototype parts with utmost precision. This level of accuracy allows automotive engineers to evaluate designs thoroughly before committing to mass production, thereby minimizing costly errors and reducing time-to-market for new vehicles and components. For aspiring automotive businesses seeking reliable CNC machines to facilitate their prototyping needs, Exact Machine Service, Inc. offers an extensive range of cutting-edge CNC equipment that meets diverse requirements and budgets.

2. Customization and Personalization

The modern automotive market demands a wide range of vehicle models and options to cater to the diverse preferences of consumers. CNC machining enables automotive manufacturers to embrace customization and personalization on a whole new scale. By programming CNC machines to create unique parts and components, automakers can cater to individual customer demands, offering bespoke features and designs. This capability not only enhances customer satisfaction but also enables automotive businesses to differentiate themselves in a competitive market. Their portfolio includes CNC machines that are well-suited for customization tasks, providing automotive companies with the tools they need to elevate their offerings.

3. Enhanced Manufacturing Efficiency

Efficiency is a key driver of success in the automotive industry. CNC machining optimizes the production process, leading to increased efficiency and productivity. Unlike traditional machining methods, CNC machines operate autonomously once programmed, eliminating the need for continuous manual intervention. This autonomous operation reduces human errors, speeds up production times, and allows for continuous operation, even during non-working hours. As a result, the automotive industry can produce higher volumes of components in shorter time frames, leading to improved supply chain management and cost savings. Automotive businesses seeking to enhance their manufacturing efficiency can rely on Exact Machine Service, Inc. to provide them with top-of-the-line CNC machines and expert advice on implementing them effectively.

4. Complex Part Manufacturing

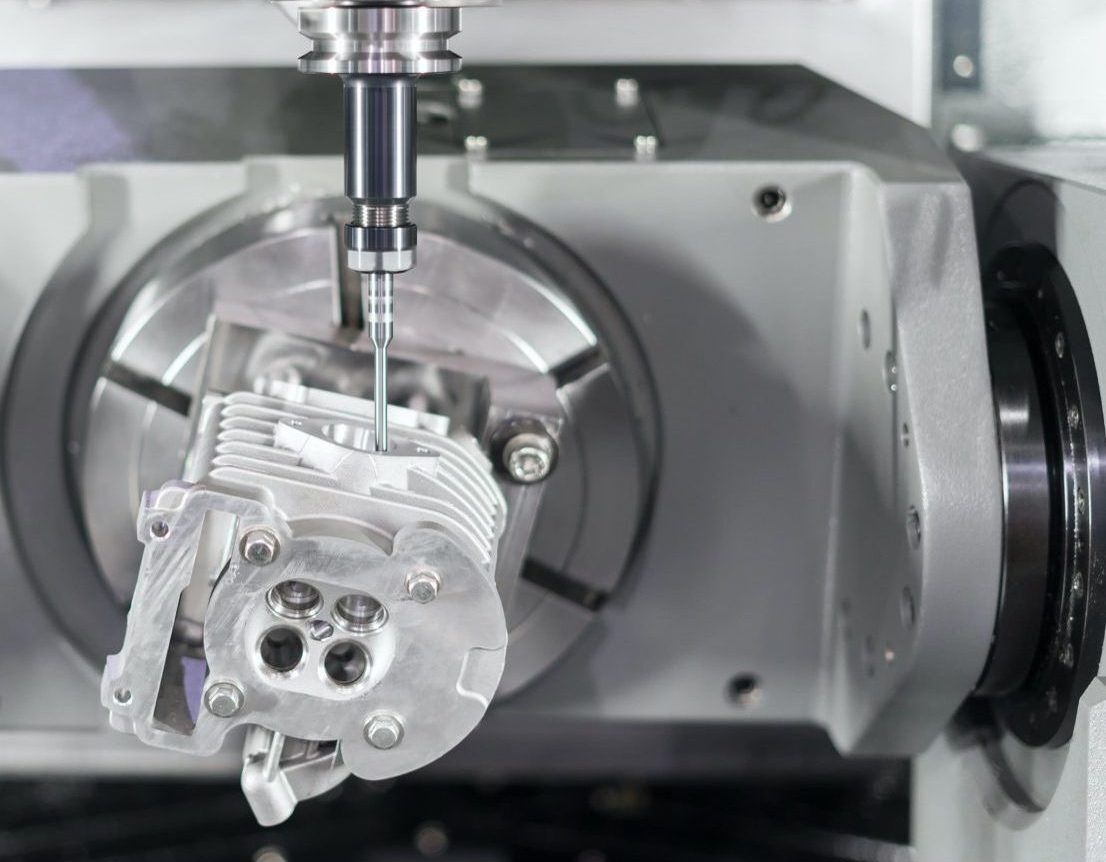

The automotive industry frequently deals with intricate and complex parts that demand utmost precision during manufacturing. CNC machining excels in this aspect, as it can accurately reproduce intricate designs and geometries with consistent quality. Whether it’s engine components, transmission parts, or intricate automotive body details, CNC machines can handle the challenges posed by these complex part designs. The ability to produce such components with precision and repeatability ensures that the final products meet the required specifications and quality standards. Exact Machine Service, Inc. understands the criticality of precision in automotive part manufacturing. Their CNC machines are carefully selected to fulfill the industry’s demands for accuracy and reliability.

5. Reduction of Waste and Costs

CNC machining’s computer-controlled precision translates into significantly reduced material waste during the manufacturing process. Traditional machining methods often generate substantial waste due to errors and inefficiencies. In contrast, CNC machines execute operations with minimal deviation from the programmed parameters, optimizing material usage and minimizing waste. This reduction in waste directly impacts production costs, as automotive companies can make the most out of their raw materials, leading to cost savings in the long run. For automotive manufacturers looking to maximize cost-efficiency through CNC machining, they offer an array of CNC machines designed to deliver optimal results while minimizing waste.