Fusing Optical Measurement Equipment with Advanced Techniques

The integration of optical, coordinate and stencil measurement technologies has resulted in

a significant decrease in defects by up to 80% in manufacturing sectors and various other

sectors.

The combination of these techniques not only makes sure the quality is excellent. But also

makes processes more efficient, reduces waste and makes the best use of resources. Now

industries can operate at peak efficiency without compromising on precision.

In this article, we will explore different meteorology technologies and how they are coming

together to change the way we understand measurements.

Exploring the Precision Measurement Spectrum

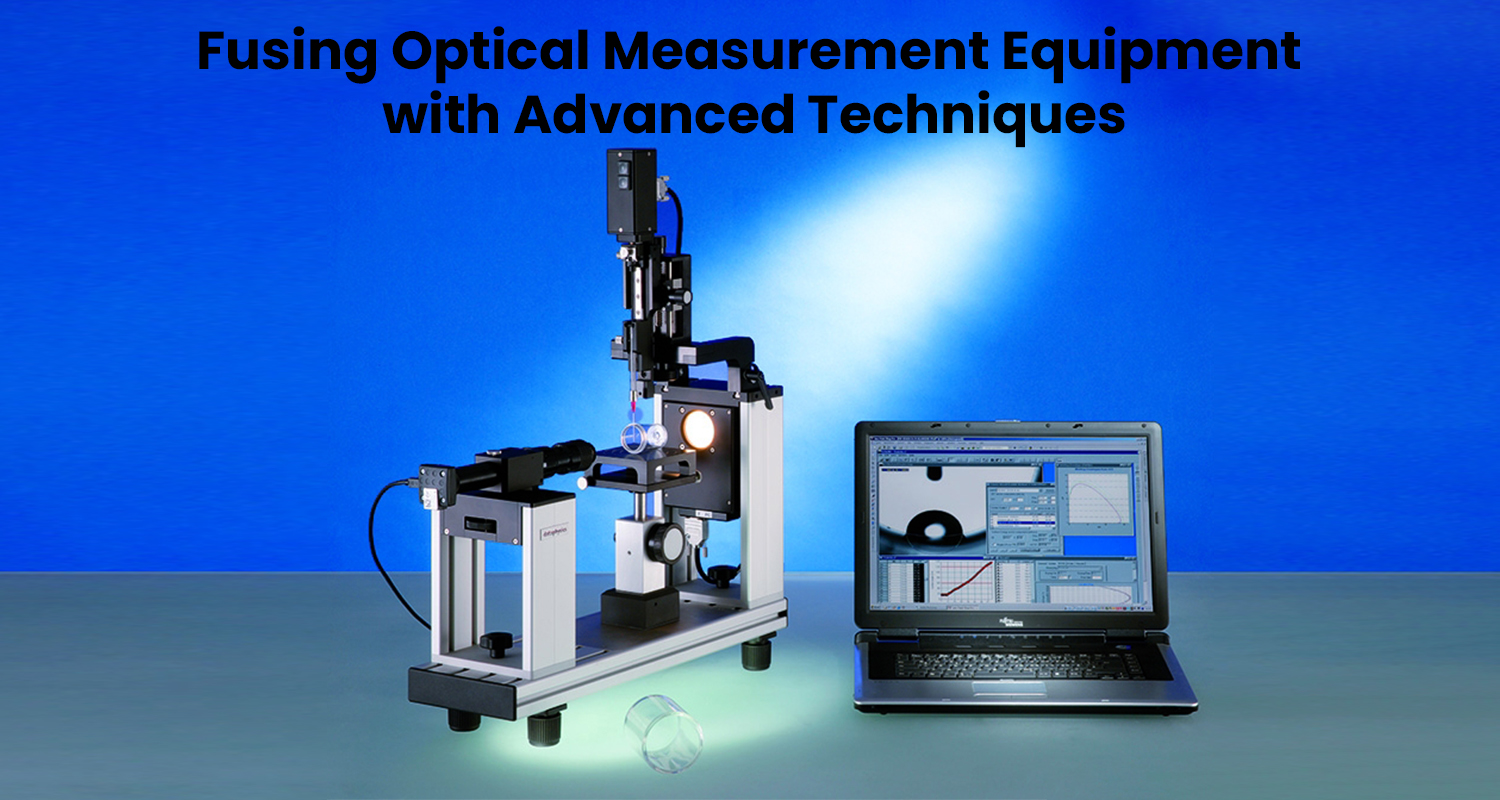

1. Optical Measurement Equipment

Optical Measurement Equipment uses light to show the small details on the surface of an

object. It is an integral part of the Optical Measurement System. These systems include tools

such as optical profilometers, interferometers, and spectrometers to measure and analyse

light and its properties. They excel in assessing attributes such as surface roughness, colour

and topography. Optical systems are great for measuring delicate surfaces and complex

shapes without having to touch them.

Industries: Aerospace, Automotive, Electronics, Healthcare, Manufacturing and Research.

Applications:

i). Aerospace and Automotive: Used to inspect critical components for defects, measure

tolerances of intricate parts, and ensure the quality of surfaces and coatings.

ii). Electronics: Employed to assess the precision of microelectronics, measure features on

printed circuit boards, and verify the integrity of solder joints.

iii). Healthcare: Utilized in medical device manufacturing to ensure the accuracy of

implantable components and the quality of medical instruments.

iv). Manufacturing: Used for quality control in industries such as textiles, ceramics, and

precision machining to measure surface textures and geometries.

v). Research: Applied in scientific research for accurate measurements of nanoscale

structures, biological specimens, and advanced materials.

2. Coordinate Measurement Systems:

Coordinate measurement systems (CMS) offer tactile accuracy by precisely determining the

exact location of an object in a specific coordinate system. Touch probes, laser scanners,

and optical sensors are integral components of these systems.

Coordinate measurement systems facilitate tactile measurements with remarkable precision,

enabling industries to validate complex parts against design specifications. CMS solutions

connect virtual design with the real world, making sure that every product meets high

standards.

Industries: Aerospace, Automotive, Manufacturing, Electronics and Engineering.

Applications:

i). Aerospace and Automotive: Used to verify the accuracy of complex assemblies, inspect

large components, and ensure compliance with design specifications.

ii). Manufacturing: Employed to measure parts during production to ensure they meet

specified tolerances and standards.

iii). Electronics: Utilized in the electronics industry to inspect components, connectors, and

ensure proper PCB assembly.

iv). Engineering: Applied in the field of engineering for reverse engineering, comparing

manufactured parts with CAD models, and assessing deformations.

3. Stencil Measurement:

In the electronics manufacturing industry, stencil measurement is very important. As

electronic components get smaller, it's becoming even more important to apply solder paste

accurately. Stencil Measurement Solutions thoroughly inspect the small holes in stencils to

make sure that solder paste is applied correctly. This technology is very important in making

perfect circuit boards. It makes the products better and more reliable.

Industries: Electronics Manufacturing.

Applications:

i). Solder Pasting: This is important to make sure solder paste is placed correctly on printed

circuit boards to solder them properly. Taking accurate measurements of stencils helps

avoid problems with soldering. This makes sure that electronic parts connect well and work

properly.

ii). High-Speed Circuitry: In devices like phones or internet equipment, if the solder paste is

not put on perfectly, it can make the signals go slower. Stencil measurement is important for

making sure that signals are sent in the best possible way.

iii). Complex PCB Assemblies: Many electronic devices have complex circuit boards with

many layers and parts. Stencil measurement is very important to make sure that complex

layouts are put together correctly.

4. Video Measuring Machines:

Video measuring machines (VMMs) are tools that connect optical measurement and tactile

measurement together. It captures images of objects by using high-resolution cameras. And

use advanced software to convert these images into precise measurements.

Imagine it as converting small dots into tiny units of measurement. The integration of optical

measurement techniques into VMMs has further elevated their accuracy. .

Industries: Aerospace, Automotive, Electronics, Medical Devices and Manufacturing.

Applications:

i). Aerospace: Used to measure complex aerospace components, such as turbine blades

and aircraft structural elements.

ii). Automotive: Employed for measuring intricate parts like engine components, transmission

parts, and chassis elements.

iii). Electronics: Utilized in the inspection of small electronic components, PCBs, and

connectors to ensure precise dimensions.

iv). Medical Devices: Applied to measure medical implants, surgical instruments, and

precision components for medical equipment.

v). Manufacturing: Used for quality control in various manufacturing processes, ensuring

accurate and consistent parts production.

The Synergy of Precision: Where Technologies Converge

To be extremely accurate, the combination of these technologies works perfectly together.

Let’s see how this combination shows itself:

.

A). Comprehensive Object Characterization : Combining optical measurement equipment, coordinate measurement systems, and stencil

measurement technologies allows for a complete understanding of an object's features.

Optical systems and coordinate systems work together to capture all the small details on a

surface. Nothing is left out or missed.

B). Enhanced Quality Control : Industries need careful quality control, and combining these technologies helps to address

this challenge directly. The video measuring machine is a unique combination of optical and

tactile features. It ensures top-notch quality control. It makes sure products meet all

requirements and go beyond what customers expect.

C). Real-time Monitoring : A Coordinate Measurement System combined with stencil measurement abilities, allows for monitoring of manufacturing processes in real-time. This teamwork ensures that the complex

parts of electronic devices are made with great care. By reducing mistakes and increasing

efficiency.

Conclusion: Advancing Precision through Integration

New ideas and advancements often come from combining different areas of study, and this

is also true for measuring technologies. By using different types of measurement systems,

industries can now achieve very accurate and detailed measurements that were not possible

before.

This fusion allows engineers to look at an object and see all its features. They can use this

information to find any differences, make improvements to the design, and make sure it

meets very high quality standards.

VIEW brand contributions in this field are great examples of what can be done through

innovation. They are very committed to creating new measurement tools that are very

accurate.

#optical measurement equipment #optical measurement system #video measuring machine #Stencil measurement

#coordinate measurement system

For More Info Visit : https://buzziova.com/