An effective supply chain strategy is a critical determinant of success. A well-designed supply chain strategy ensures that products are efficiently sourced, manufactured, and delivered to customers, optimizing operational efficiency and customer satisfaction. Central to this strategy is the use of inventory management system software, which plays a pivotal role in streamlining inventory control and improving overall supply chain performance. In this blog, we will explore the key steps to develop an effective supply chain strategy and highlight the significant role of inventory management software in this process.

Supply chain strategy with inventory management software

A successful supply chain strategy focuses on meeting customer demands, increasing responsiveness, enhancing customer value, supporting financial success, and developing a strong network. Faster delivery, greater efficiency, and quicker cash flow should be the main objectives of effective supply chain management.

A strong supply chain management plan can also lessen risk and the effects of supply chain disruption. Faster recovery will be facilitated by processes and systems that can help you preserve or increase your competitive advantage.

Step 1: Assess Current Supply Chain Performance

Before crafting a new strategy, it is essential to evaluate the current state of your supply chain. This involves analyzing key performance indicators (KPIs) such as inventory turnover, order fulfillment rates, lead times, and customer satisfaction levels. Identifying areas of improvement and pain points will help set clear objectives for the new strategy.

Step 2: Define Supply Chain Objectives

Based on the assessment, establish specific and measurable objectives for your supply chain strategy. These objectives should align with the overall business goals and address the identified areas for improvement. Common objectives include reducing inventory carrying costs, improving delivery times, enhancing demand forecasting accuracy, and optimizing supplier relationships.

Step 3: Align Supply Chain with Business Goals

An effective supply chain strategy should be closely aligned with the broader goals of the organization. Collaborate with key stakeholders from different departments to understand their requirements and expectations. This cross-functional approach ensures that the supply chain strategy contributes to the overall success of the company.

Step 4: Optimize Inventory Management with Software

Inventory management is a critical component of supply chain efficiency. Utilizing inventory management software allows businesses to automate and optimize inventory control processes. By centralizing data and providing real-time visibility, the software enables better demand forecasting, stock replenishment, and timely order fulfillment.

Step 5: Choose the Right Inventory Management Software

Selecting the appropriate inventory management software is crucial to the success of your supply chain strategy. Consider factors such as scalability, integration capabilities with other systems, user-friendliness, and data security when making your decision. The software should align with your unique business needs and support your supply chain objectives.

Read More – Software development company Singapore

Step 6: Implement Demand Forecasting Techniques

Accurate demand forecasting is vital for efficient inventory management. By leveraging historical sales data, market trends, and customer insights, businesses can predict demand more accurately. Inventory management software with demand forecasting features can significantly improve the accuracy of these predictions, ensuring optimal inventory levels.

Step 7: Enhance Supplier Collaboration

Collaboration with suppliers is a key element of an effective supply chain strategy. Establishing strong partnerships with suppliers enables better communication, reduced lead times, and increased reliability in the procurement process. Inventory management software with supplier portals can facilitate seamless collaboration and real-time updates on inventory status.

Step 8: Monitor and Measure Performance

Regularly monitor and measure the performance of your supply chain against the defined objectives. Utilize the reporting and analytics features of your inventory management software to track KPIs and identify areas that require further improvement. Timely performance reviews allow for continuous refinement and optimization of the supply chain strategy.

Step 9: Adapt to Changing Market Dynamics

The business landscape is constantly evolving, and supply chain strategies must be agile enough to adapt to changing market dynamics. Be prepared to revise your strategy as needed, taking into account factors like shifting customer demands, economic conditions, and technological advancements.

Step 10: Foster a Culture of Continuous Improvement

Encourage a culture of continuous improvement within your organization. Involve employees at all levels in identifying opportunities for enhancement and innovation. Emphasize the importance of collaboration and feedback to drive ongoing improvements in supply chain efficiency.

Read More – Software development in Singapore

Using software to execute your supply chain strategy

Implementing your supply chain plan using software

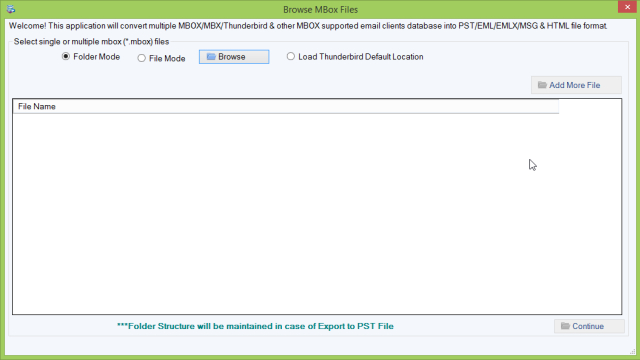

Having the appropriate software and technology to support its implementation is essential for a successful supply chain strategy. You’ll be more productive and save time if you use the right software. Additionally, it can aid in reducing supply chain risks, hence protecting already slim revenues.

Supporting software examples include:

- Systems for managing warehouses. Real-time information from a contemporary database can improve stock visibility and streamline warehouse operations. To enhance warehouse flexibility, responsiveness, safety, security, and customer service, it can be connected to already-existing ERPs or business systems.

- Choosing a technology. The fastest picking operations are achieved with the use of automated picking software and hardware, such as pick to light or voice.

- Inventory management. Using spreadsheets or other simple tools to estimate inventory demands is no longer necessary thanks to specialised inventory optimisation solutions. In order to control irregular market demand or supply chain volatility and lower the risk of stockouts, they can immediately deliver precise and trustworthy data.

More sophisticated technology, like robots, drones, and artificial intelligence, can also support supply chain strategies, depending on the objectives of the firm.

Please contact a member of our team to schedule a demo if you’d like to talk about your supply chain strategy and how EazyStock can support inventory management.

Conclusion

Developing an effective supply chain strategy is a complex undertaking that requires careful planning, collaboration, and the right tools. Inventory management software is a valuable asset in this process, empowering businesses to optimize inventory control, enhance demand forecasting, and improve supplier collaboration. By aligning the supply chain strategy with business goals and fostering a culture of continuous improvement, organizations can achieve operational excellence, reduce costs, and deliver exceptional customer experiences. Embrace the power of inventory management software to transform your supply chain and stay ahead in today’s dynamic business landscape.