Selecting the right plastic mold maker is a process that requires careful consideration and diligent research. A multitude of factors come into play, which can significantly impact the quality of your finished product, your production efficiency, and your bottom line.

In this article, we delve into the specifics of what to look out for when choosing the perfect partner for your plastic molding needs. We’ll touch on the importance of industry experience, technology, design capability, production capacity, price, quality assurance, and customer service in this decision-making process. Understanding these key factors will guide you towards a plastic mold maker who can deliver a seamless and professional service tailored to your particular industry and product specifications. Let’s get started.

Expertise and Experience

Expertise and experience reign supreme when considering a potential plastic mold maker. The complexities of plastic mold making require a provider with a deep knowledge base and a plethora of practical experiences. A company with a long-standing presence in the industry implies a proven track record of quality and reliability. Experienced mold makers are equipped with essential insights into material behavior, mold design complexities, and production challenges, which are invaluable when it comes to making efficiencies and cost savings in complicated projects.

Furthermore, they are able to anticipate and mitigate potential issues, providing solutions before they even transpire. Their proficiency implies familiarity with a wide range of diverse plastics and processes, assuring customers they can meet unique project needs with precision and efficiency.

Quality and Precision

In choosing a plastic mold maker, it is essential that you look through whether they acquire quality and precision. In fact, in the world of mold making, even the slightest error or inaccuracies can lead to significant product defects, wasted resources and a negative impact on the final product’s performance. Therefore, it’s imperative to opt for a plastic mold maker who is recognized for their uncompromising commitment to quality and precision.

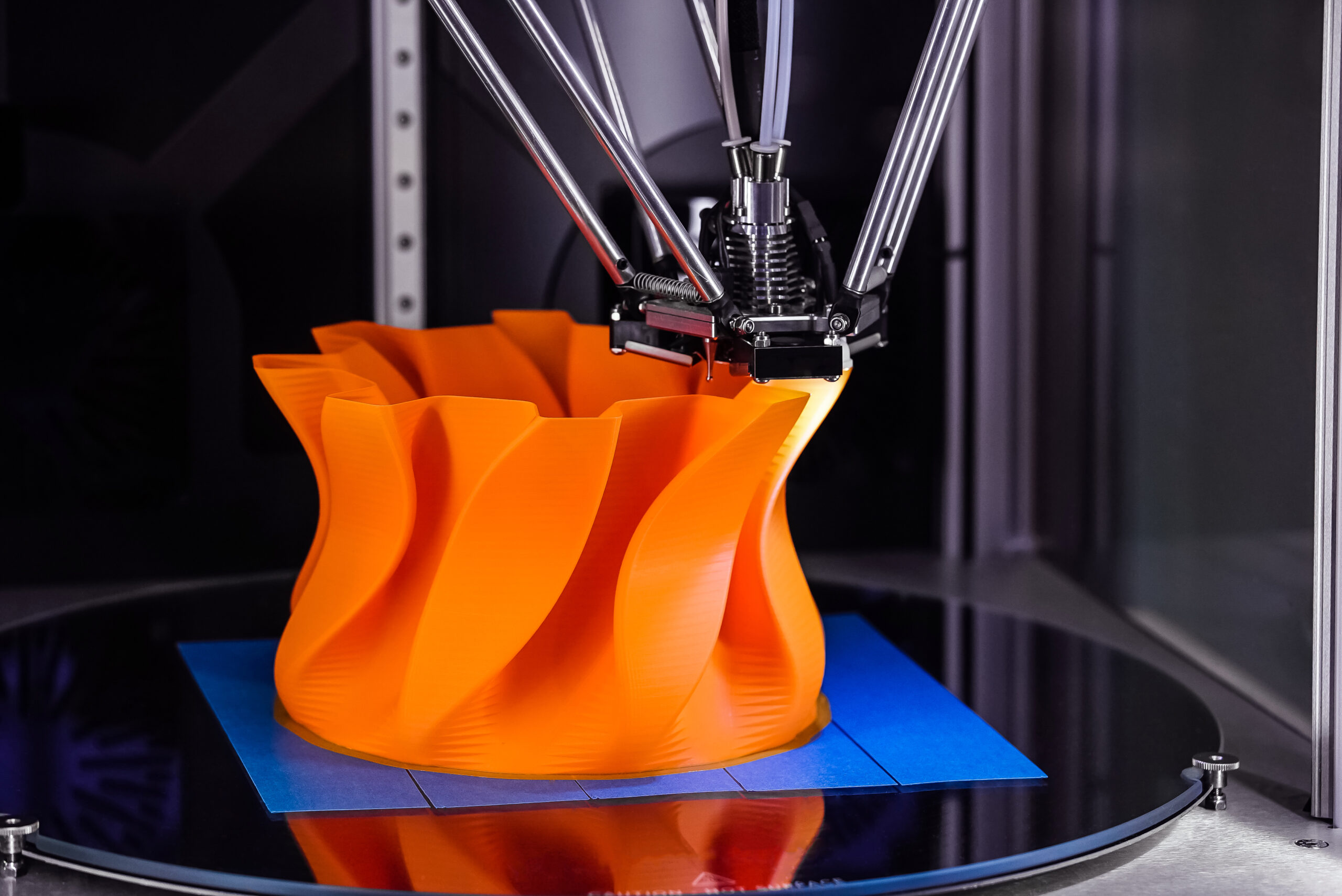

Furthermore, an ideal mold maker will rely on state-of-the-art technology and meticulous quality control processes to ensure each mold meets the highest standards of precision, from design to manufacturing. They will also conduct rigorous inspections and tests to guarantee the mold is free from flaws which might compromise its function.

Design Capabilities

Comprehensive and innovative design capabilities ensure that the mold maker can effectively translate your product concepts into tangible, high-performance molds that will accurately reproduce your design in plastic. Look for a mold maker who uses advanced Computer Aided Design (CAD) technology, and can showcase a portfolio demonstrating varied and sophisticated design output.

Good mold makers should also be able to exhibit a collaborative approach, working closely with clients to optimize designs for manufacturability, reduce production costs and improve product functionality. They also need to be proficient in managing complex mold designs with multiple cavities or intricate details. As such, a mold maker’s design capability is a critical aspect that directly affects the lead-time, production cost, and overall quality of the final product.

Manufacturing Capabilities

The manufacturing capabilities not only involve the ability to produce molds to exact specifications, but also their capacity to meet demand scales and deadlines, without compromising on quality. A right mold maker should employ state-of-the-art machinery and equipment, ranging from high-speed CNC machinery, EDM machines to precision grinding machines. This will ensure that they can handle complex geometries, tight tolerances, and deliver on time, even for larger orders.

In addition, consider whether they are able to provide an end-to-end service that encompasses mold design, mold making, testing, modification and maintenance. This can save you time and reduce the need for coordination among multiple suppliers.

Material Expertise

Different plastic materials exhibit varied properties, meaning they respond differently during molding processes. Therefore, the mold maker you choose must have deep-seated knowledge of a wide range of plastic materials, and understand how to mold each one to achieve the desired results. Whether it’s understanding the shrinkage rates of different materials, their flow behavior or how quickly they cool, a seasoned mold maker will use this knowledge to create molds that account for these factors, providing a high-quality and consistent output.

Also, plastic mold makers should be able to advise you on the most suitable plastic materials for your specific product requirements, potentially offering more cost-effective or performance-optimizing alternatives.

Time and Cost Efficiency

In an increasingly competitive market, manufacturers need to deliver products on time and within budget. A mold maker that prioritizes efficiency can significantly streamline your production process, reducing time-to-market and increasing your competitive edge. Therefore, you have to look for mold makers with a reputation for delivering projects on schedule, as delays can increase costs and upset deadlines.

Actually, cost efficiency doesn’t necessarily mean the cheapest service. Instead, it denotes getting optimal value for your investment. Factors such as innovative technology use, waste reduction measures, energy-efficient operation, and process optimization all contribute to cost-efficiency.

As you partner with a time and cost-efficient mold maker, it not only influences your direct production costs but also plays a crucial role in enhancing customer satisfaction and your overall business success.

Customer Support and Communication

It is also important to consider the customer support and communication as you select the right plastic mold maker for your project. Effective customer support ensures that you have a dedicated point of contact throughout the manufacturing process, offering timely assistance and addressing any concerns that may arise. A reliable mold maker should maintain transparent and open lines of communication, keeping you informed about the project’s progress, potential delays, and any adjustments needed. Their ability to listen actively and understand your specific requirements is crucial in delivering a high-quality end product.

Additionally, a mold maker that values effective communication will be more responsive to your inquiries, providing timely updates and seeking your feedback to ensure that the final mold aligns perfectly with your expectations.

Key Takeaway

Overall, the success of a manufacturing project can be greatly impacted by the choice of a plastic mold maker. And as you consider the factors mentioned above, you can then make an informed decision and select a plastic mold maker that aligns with your specific project requirements, ensuring a successful outcome.